|

|||||

B-pillar Reinforcement CAD

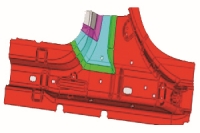

B-pillar Reinforcement Mesh

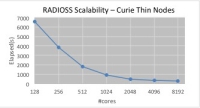

RADIOSS Scalability Study

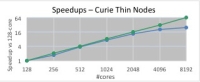

RADIOSS Speedup Curve

|

|

|

Home > News > Members and Partners News > Altair

December 9, 2014 - Découvrez comment les solutions MATLAB permettent de répondre aux problématiques liées à la manipulation de données massives lors d’un séminaire gratuit d’une journée le 15 janvier à Paris. Au cours de ce séminaire, nous vous présenterons en matinée le workflow suivant pour analyser vos données :

L’après-midi, vous pourrez participer à un Workshop Calcul Parallèle et/ou à une Master Class Déploiement d’Applications :

|

| November 19, 2014 - Toward Better Failure Prediction for

Crash Simulations using HPC

PSA Peugeot Citroën collaborated with Altair, Ecole Polytechnique Laboratoire de Mécanique des Solides (LMS) and PRACE to perform a study of automotive crash rupture simulations, investigating ways to improve material failure criteria and better predict cracks. Using Curie, one of the ten most powerful supercomputer in the world, designed by the company BULL and operated by them at Très Grand Centre de Calcul du CEA (TGCC), project engineers ran huge (15M element) solid models of some component using a very fine mesh in order to simulate material failures. The massive parallelism enabled by Altair RADIOSS on the Curie system achieved unprecedented results, with levels of performance that would not have been possible on a standard computer or cluster.

The second largest carmaker in Europe, PSA Peugeot Citroën (PSA) recorded sales and revenue of €54 billion in 2013. With its world-renowned brands, DS, Peugeot and Citroën, PSA sold 2.8 million vehicles worldwide in 2013, of which 42% outside Europe. PSA is a European leader in terms of CO2 emissions, with an average of 115,9 grams of CO2/km in 2013. PSA has sales operations in 160 countries and is also involved in financing activities (Banque PSA Finance) and automotive equipment (Faurecia).

As automotive regulations impose lower and lower CO2 emission levels, manufacturers face serious challenges in decreasing design structure mass by using higher strength-to-weight ratio materials. However, introducing new materials into a design process is not a simple undertaking; design rules and numerical tools must evolve to comprehend the characteristics -- and evaluate the potential failures – of such materials. Otherwise, there is risk in delaying production awaiting reliable design direction from simulation, or (worst case) having to redesign a part late in the design cycle. In addition, due to the large, nonlinear deformations involved in simulating crash or rupture events, proper material failure criteria is essential to results accuracy. Evaluating new materials, which by definition lack the testing and refinement over time of conventional materials, also typically results in applying higher safety factors for the design which can lead to oversizing of structural parts. To improve its knowledge in assessing predictive rupture models, and to identify a viable solution for testing ruptures on a massive scale, PSA engaged with Altair through PRACE to evaluate the robustness of advanced failure criterion for steel sheets using RADIOSS, the market-leading analysis solver for crash simulation in Altair’s HyperWorks CAE software suite.

First, Altair engineers ported RADIOSS to Bullxmpi for the Curie supercomputer allocated to the study. This porting included the optimization of the setup of RADIOSS under Bullxmpi to obtain ideal performance. The efficiency of the solution based on Bullxmpi was evaluated and improved using industrial car crash models ranging from 1 to 10 million of elements. Then, two specific models were developed to study rupture of a B-pillar component with mesh size requirement of 75μm element length.

Altair had to optimize the code to handle the large simulation models, especially contact treatments inside the very fine mesh part; the project also required optimizing several I/O treatments, and engineers intensively used Intel tools like Vtune Amplifier to localize algorithms that needed to be improved. These optimizations helped Starter performance and were also useful for Engine performance related to contact sorting. In addition, Altair engineers implemented a specific material law and a rupture model in RADIOSS, which was developed through an “Industrial Fracture Consortium” including MIT, Ecole Polytechnique and industrial partners like PSA. The implementation of both law and model was validated with respect to tests on specimen and results of the original implementation by Ecole Polytechnique (LMS). Domain decomposition algorithm was tuned to optimize this material law regarding parallel efficiency.

PSA was pleased with the outcome of the study -- without access to this type of large scale supercomputer system it would have been impossible to consider running such a large simulation problem in a reasonable amount of time. Key outcomes:

The achievements obtained during this project help companies like PSA to be ready to handle increasingly complex simulations and to evaluate future needs more precisely in term of computational resources for evolving rupture simulation projects. The organizations involved plan to continue this work via a regular PRACE project to study the behavior of the rupture of this B-pillar component as well as some other components through a full vehicle crash simulation. We acknowledge PRACE for having awarded us access to resource machine Curie based in France at TGCC/CEA. |